MTB Disc Brake Pads

For more years than we would care to admit, we have been engineering performance braking components. We cut our teeth in motorsport, delivering braking products that repeatedly racked up international victories.The RWD range of MTB disc brake pads comprises two material formulations. Both having been developed, tested and fine tuned over a period of two years. Where applicable, RWD disc brake pads are supplied with high strength return springs.

All of our development takes place in the stunning Yorkshire Dales, England. We spend countless hours perfecting our materials on the very trails that you will be using them. Testing takes place all over the world by real riders using real bikes in real weather. This is why we can be certain that there is a RWD disc brake pad formulation to suit your riding. We firmly believe that you cannot find a better disc brake pad for your bike.

First things first - why do we have different material formulations?

The answer is quite simple, one material cannot cope with the wide variety of conditions that you will experience whilst riding. As a brief summary, Organic friction material is the preferred choice for summer, suited to cross country and leisure riding. it has a consistant performance across a wide operating range but is not generally suited to wet and/or harsh environments. Sintered metal material is a higher friction compound - perfect for demanding trail riding and a good choice for downhill. It works best with some heat in the system and revels in wet and gritty conditions. To learn more about each material click on the tabs above.With a vast array of friction products available you may have come across other formulations such as semi-metallic, kevlar or even dual compound pads amongst other. We routinely test and compare a wide range of alternative materials and will only bring to market formulations that meet our exacting standards. Don't beleive claims about extra long life or that "this material is the best of all worlds". Different conditions or even riding styles require different friction materials. Once fitted to a bike, each indivual pad faces a unique life and longevity is hugely dependent on a number of circumstances, such as bedding in procedure, riding environment, cleaning rountine etc.

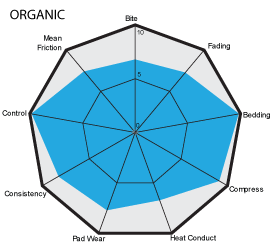

Organic Friction Material

RWD Organic brake pads offer a consistent level of friction whilst being relatively low-wearing on the disc. The medium density and compressibility properties of this material mean that the pad has an excellent level of modulation and control. Organic disc brake pads demonstrate good cold performance, offering consistent "bite" from the outset. The green performance (from new) is equally as consistent with the pads bedding to the disc surface with relative ease and speed.

This material will perform equally and consistently in all conditions but due to the softer compound will be subject to an increased wear rate when used in sandy and/or wet environments.

Sintered Metal Friction Material

Sintered brake pads offer a stronger initial "bite" with a higher mean friction level than the Organic material. This improved level of performance is due to the inclusion of copper fibres within the friction material mixture and ensures that RWD sintered disc brake pads are amongst the highest performing available anywhere today. The Sintered formulation has a higher density and lower compressibility than its Organic equivalent, which makes it a very hard compound. Due to its hardness a Sintered pad has a longer lifespan than an Organic pad making this the best value for money option.

The performance of RWD Sintered pads remains consistent in wet conditions and due to the hardness of the material these pads are also very well suited to sandy trail centre riding. The higher friction level and wider operating temperature range also make this material a very good candidate for downhill riding.*Please be advised that some discs are unhardened and therfore only suitable for use with softer organic formulations. If your disc is marked 'Resin pads only' then you should opt for RWD Organic disc brake pads. This will safeguard from scoring and premature wear of the disc when coupled with a harder or sintered brake pad.

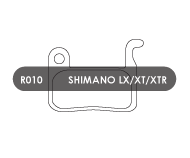

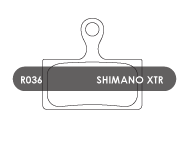

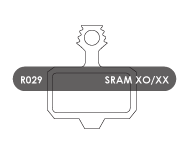

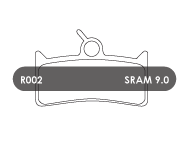

The Range

Below is the current range of disc brake pads that we offer. We try to supply the majority of current applications and will add new references as they become available.

Performance Data